Capital Tape’s roll-slitting service stands as a testament to precision and efficiency in the tape manufacturing industry. Specializing in converting master rolls of tape to custom sizes, we cater to a wide range of industries requiring exact specifications.

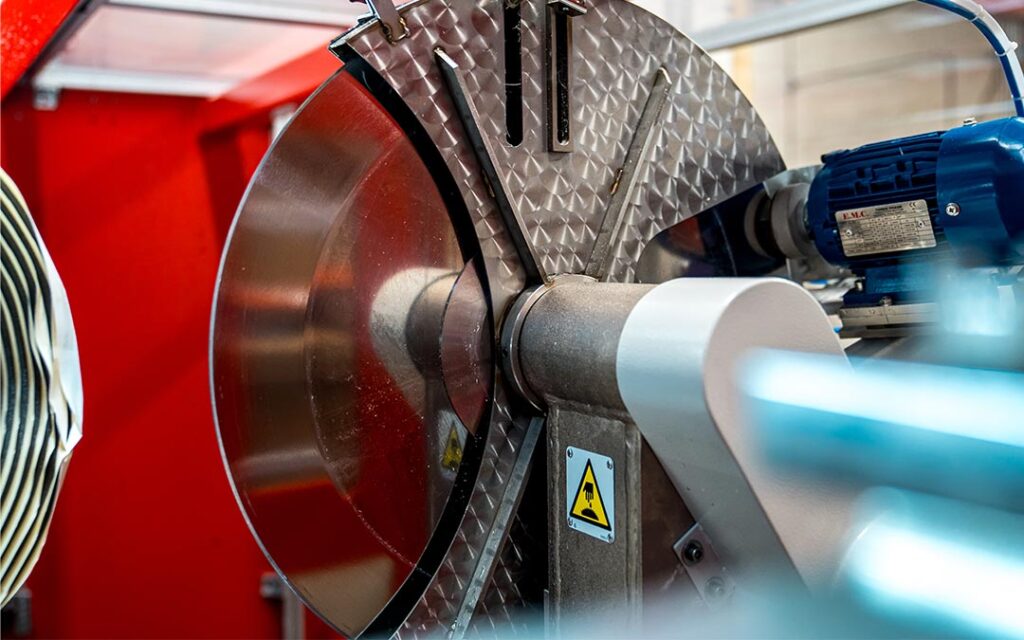

Precision Roll Slitting Technology

Our precision roll slitting machinery allows Capital Tape to custom cut an expansive range of adhesives, foam tapes, glazing tapes, ultra high bond tapes, low-density tapes, polyethylene, and more.

Capital Tape Roll Slitting Range

Our advanced roll-slitting lathe uses a precision saw blade to cut tape to consistent and exact widths— as narrow as 0.125 inches and as wide as 62 inches (min/max dependent on material and master roll diameter).

- Minimum width: 0.125”

- Maximum width: 62.0”

- Maximum roll diameter: 29”

The process of roll slitting at Capital Tape involves state-of-the-art machinery and skilled technicians who ensure each cut is precise and consistent. The master rolls, which can have a maximum outside diameter of 29 inches, are carefully handled to maintain their integrity throughout the slitting process. This attention to detail guarantees that the final product meets the high standards expected by our clients. One of the significant advantages of Capital Tape’s roll slitting service is its versatility. By accommodating such a broad range of widths, the company can serve diverse market needs.

Experts in Adhesives (and Non-Adhesives)

Whether you know exactly what you need, or need a bit of guidance, Capital Tape’s experts knows exactly which tape or adhesive is the best for your needs. We offer variety of tapes, including single-sided, double-sided, foam, and specialty tapes, all of which can be precisely cut to your precise specifications. This adaptability ensures that you receive tapes that not only fit your dimensional needs but also meet functional requirements such as durability, adhesive strength, and environmental resistance.

Tirelessly Dedicated to Quality

Quality control is a cornerstone of Capital Tape’s roll-slitting service. Each roll undergoes rigorous inspection both before and after the slitting process. This ensures that any defects or inconsistencies are identified and addressed promptly, maintaining the high quality that clients have come to expect. Our advanced equipment allows for efficient production without compromising accuracy, enabling Capital Tape to meet tight deadlines and high-volume orders without sacrificing quality.

Industry-Best Turnaround Times

The lead times for standard cuts and sizes (1/4″, 3/8″, 1/2″ widths) is an industry-best 1-2 business days (and many times we turn same- or next-day!) For non-standard sizes (3/16″, 5/16″ widths) and custom requests, we boast super-fast turnaround times that average only 3-5 business days. We have most tapes in stock at all times, but if any product needs to be ordered, we generally can have it shipped in, slit to size, and shipped out to you within two weeks or less. Capital Tape prides itself on meeting the evolving needs of our clients, quickly and with a smile.

At Capital Tape, our motto is simple: WE CUT TAPE!

Get a Quote or Request Samples

Need tape? You can get a 24/7 online quote through our website or send us a request for samples and we’ll get tester rolls of the tape you need out to you so that you can touch and feel it before you order!