Foam tape is a versatile and essential component in various industries, providing crucial sealing, cushioning, and insulating properties. However, one issue that can arise during the production and use of foam tape is the formation of gaps. These gaps can compromise the tape’s effectiveness and lead to product failures. Understanding the causes of gaps in foam tape and how to prevent them is critical for manufacturers and users alike.

Excessive Tension During Manufacturing Causes Gaps in Foam Tape

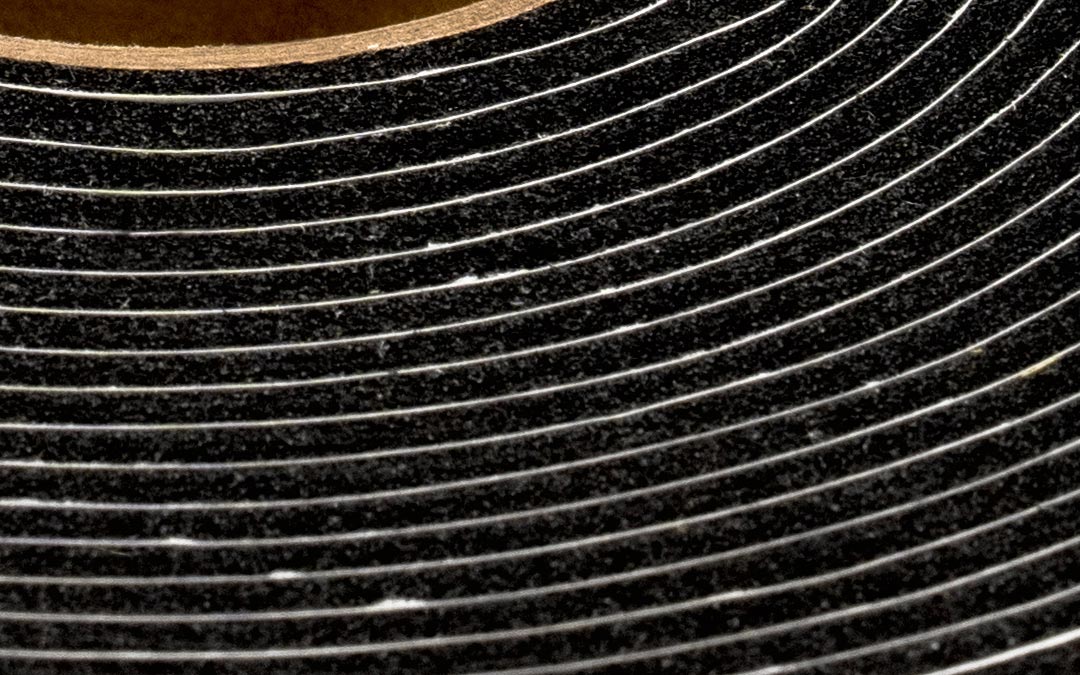

One of the primary reasons for gaps in foam tape is excessive tension applied during the manufacturing process. Foam tape is produced in rolls, and the tension must be carefully controlled to ensure even distribution across the entire roll. When the tension is too high, it can stretch the foam unevenly, leading to inconsistencies in the foam structure. These inconsistencies manifest as gaps within the tape, which can affect its adhesive properties and overall performance.

Manufacturers need to implement stringent tension control measures during production to prevent this issue. This includes using precise tension control equipment and regularly monitoring and adjusting the tension as needed. By maintaining consistent tension, manufacturers can ensure the foam tape remains uniform and free of gaps.

Gaps in Foam Tape from Stored Energy During Shipment

The problems with gaps in foam tape do not end with the manufacturing process. Another critical factor is the handling and storage of the foam tape rolls during shipment. The tension applied to the logs of tape during manufacturing stores energy within the material. During transportation, this stored energy can be released, causing the foam tape to cone or form gaps.

Proper handling and storage conditions during shipment are essential to mitigate these effects. This involves ensuring that the foam tape rolls are not subjected to excessive movement or temperature fluctuations, which can exacerbate the release of stored energy. Additionally, using appropriate packaging materials and techniques can help maintain the integrity of the foam tape rolls during transit.

Commitment to Customer Satisfaction

At Capital Tape, we are dedicated to ensuring customer satisfaction by providing high-quality foam tape products and addressing any issues that may arise. While we do not manufacture tape, we remain dedicated to offering the highest quality, most reliable products, and we are committed to resolving any concerns related to tape or liner defects.

If you encounter any issues with gaps in your tape or any other defects, please do not hesitate to contact us. Our team is ready to assist you and find a satisfactory resolution to meet your needs and expectations. Your satisfaction is our priority, and we are willing to go to any reasonable length to address and rectify any problems.

Contact Information

For any concerns or inquiries, please reach out to us:

Phone: 1-888-888-TAPE

Hours: Mon-Fri: 8am – 4:30pm

Email: [email protected]

At Capital Tape, we value our customers and strive to provide solutions that meet their needs and expectations. Remember, your satisfaction is our priority, and we are committed to resolving any concerns related to tape or liner defects. Contact us, and we will work together to find a satisfactory resolution.

By understanding the causes of gaps in foam tape and taking proactive measures to address them, manufacturers and users can ensure the performance and reliability of their foam tape products.

Resources and More Information

Check out our troubleshooting tips and frequently asked questions for more answers and follow us on LinkedIn for more tips, product information, and industry news.